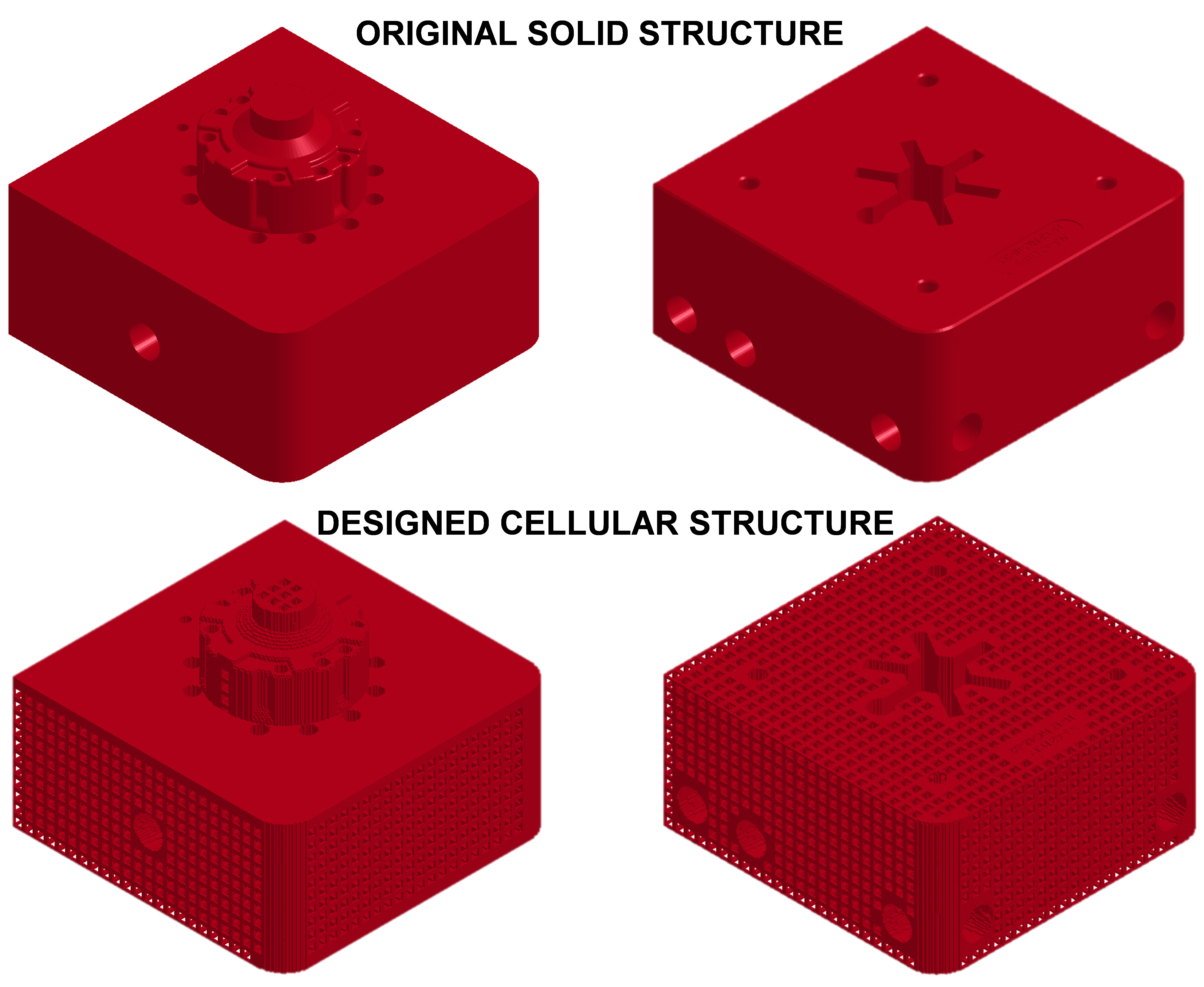

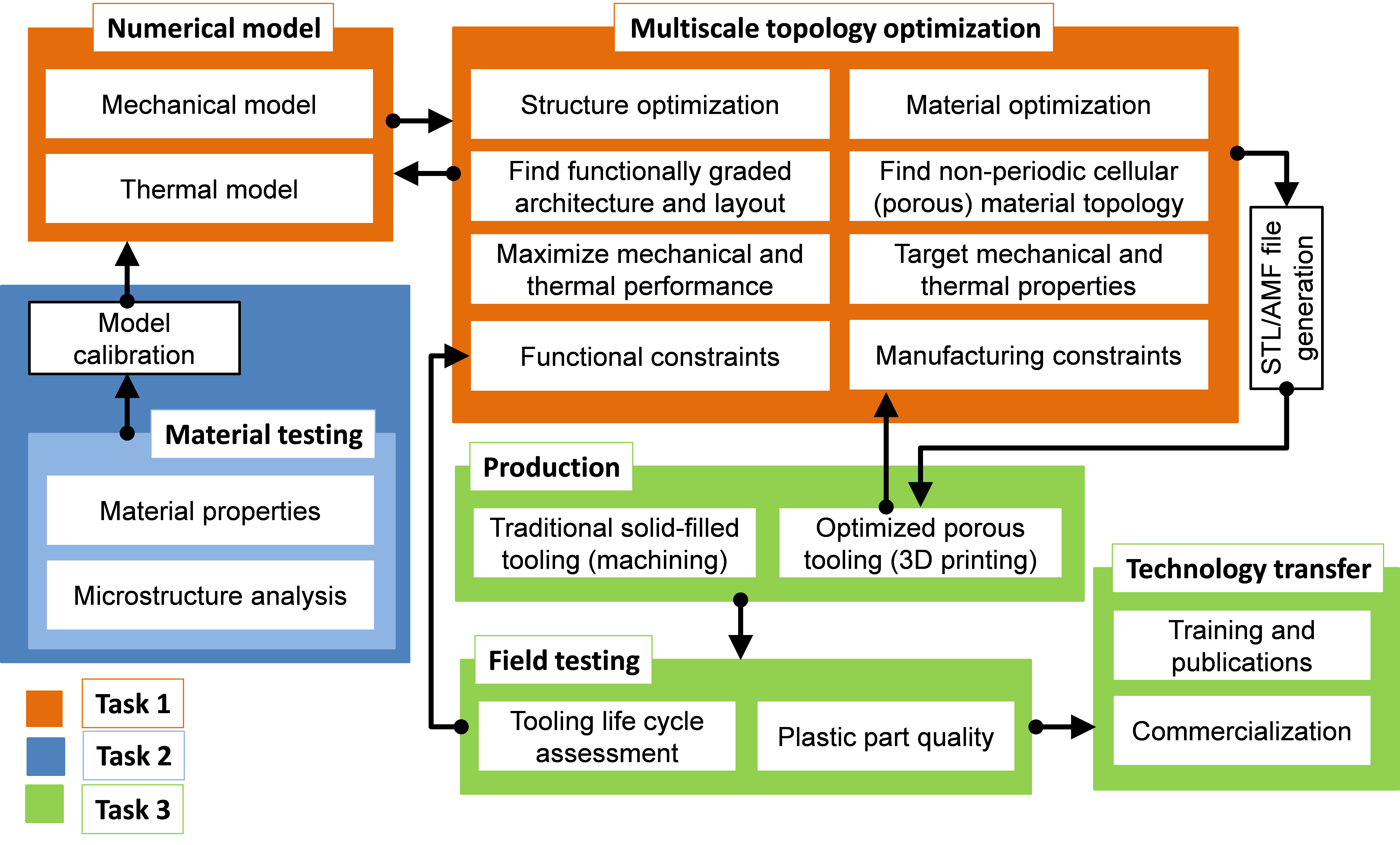

The proposed research aims at reducing the cost and increasing the performance and versatility of U.S.-manufactured plastic injection tooling (dies and molds) through experimentally supported structural design optimization methods and metal additive manufacturing. Additive manufacturing allows complex injection tooling production but is about 50% more expensive than traditional machining. Our proposed multiscale thermo-mechanical topology optimization approach leads to the generation of lightweight, high-performance, and cost-effective injection tooling through additive manufacturing. A 30% cost reduction and a 20% performance increase are expected with the optimized design.

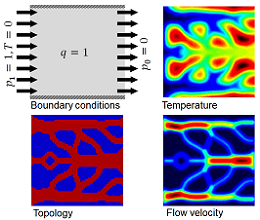

In order to address cost reduction and increased performance of U.S. injection tooling through metal additive manufacturing, our research involves three interrelated tasks: (1) optimal injection tooling design, (2) material testing and analysis, and (3) production, field-testing and technology transfer and commercialization